| Evaporator |

|

I made seven EVAs with this project.

Photographs are three EVAs manufactured as an experiment first.

(They are 1.6 inches, 1.2 inches and 0.9 inches of Vapochill-cmpatible

from the left.)

Incidentally, it was 1.4 inches that was used for Ultra vapo.

Inside structure is a top secret.

As for the strong point of the structure.

It has enough evaporating area though it is in the little body.

The flow way to keep an appropriate vapour-flow speed.

The structure that thermal resistance is small.

The highest-performance thing was used for "Ultra vapo" in seven

EVAs which I made.

The thermal resistance calculated from evaporating temperature and P4 dummy

core temperature was a 0.08 centigrade /W.

I am believed this value to be the highest value.

|

|

Refrigerating unit

|

|

accumulator

The danger of the liquid return toward compressor occurred because the

position of EVA became the top from compressor.

Therefore, it was decided that I made accumulator.

Because it didn't have a suitable part, I combined copper pipe, and made

it.

Oil must be returned with the pipe circuit of the refrigerator securely.

Therefore I learned the structure of accumulator in the reference book.

|

Site glass

If refrigerator unit works, refrigerant circulates in that inside.

It is common to want it when a person wants to see it if a person can't

see it.

It is effective when the amount of refrigerant is adjusted though it was

installed for the desire that it wanted to see it.

|

Pencil drier

It is one of the composition parts of the Vapo upgrade-kit.

(This is a present to Mr.Simantogawa from Mr.null of the agency of ASETEK.)

A pencil drier is suitable for the little system though a drier for refrigerator

can't be used because a drier for refrigerator is too big.

A desiccant and strainer are in the pencil drier.

It is absolutely necessary because the thin capillary tube of the inside

diameter is used.

|

Compressor

It was taken out from the portable air-conditioner of the air-conditioning

ability 1000W/hour which "CORONA CORPORATION" manufactured.

This compressor is estimated to be the rotary compressor which "Matsushita

Refrigeration Company" manufactured.

It uses R22, it can get lower temperature than R134a.

And, because it is the horizontal-fixed type, the height of the system

can be made low.

Displacement of it is about 30cu.-ft./hour, and estimated output will probably

be 1/5HP.

These ability specifications aren't big like the Recipro compressor which

Prometeia and EVA3 have.

But, low temperature performance as the expectation is given to a system

because it is the excellent compressor which can keep high volumetric-efficiency

even at the time of the high compression ratio.

After I cut off an unnecessary pipe then, an access valve was installed

in the high pressure side as well for the vacuum work.

|

Condenser

The condenser which composed Vapo-SLOT was used.

Oil inside the condenser and dirt were washed with the cleaner solvent

for the brake.

After it dried, nitrogenous gas was enclosed inside.

Then, a condenser was fixed on the base seat of the compressor.

The condenser of Vapo-SLOT is small.

The round hole of the condenser cover was clipped in the square to increase

those effective areas.

And, all the flow of the air passes through the condenser by shroude made

of the rubber.

|

Capillary tube switching valve

The pressure to condense it by temperature of the season changes greatly.

Therefore, two capillary tubes which length is different from are changed,

and it is used.

And, it is used to shorten the useless waiting time until it gets cold

after a switch is made on.

This form is not my original. It is the technique being used in Japan a

little.

A switching dialect is the part of the pilot of 4 direction switching valve

used for the package air conditioner.

4 direction switching valve is the part used because air-conditioning and

heating are cut and a place is taken.

The thing which I used is the parts number VS6100B 4190 of "RANCO

JAPAN LIMITED".

Precious 4 direction switching valves were collected from the scrapped

air conditioner, and Mr. asuta gave them to me.

I appreciate him again in this place!!!

One capillary tube is built in in the case of EVA of the Vapo form by the

return pipe of the bellows.

Therefore, a meeting part becomes necessary by all means when it is when

two capillary tubes are used.

This processing is very difficult.

Or, a diameter in my necessary capillary tube was 0.6mm or 0.5mm.

How to obtain it was limited.

1700-foot exorbitant length is ordered in the factory.

Or, perseverance researches the stock of the circulation goods well.

Or, a capillary tube on the market is squeezed by itself more thinly.

I have ever made it by myself. But, fortunately it could get it from Mr. MAZ this time.

They are precious goods. I appreciate him now!!

|

Solenoid Valve

When refrigerator unit stops, refrigerant which disperses within the unit

is returned to compressor, and refrigerant melts into the oil stored in

compressor.

Therefore, the condition which doesn't have refrigerant at the time of

the refrigerator unit start happens, and the phenomenon which doesn't get

cold soon occurs.

This phenomenon is said as "nekomi" (if it is translated directly,

"falls asleep") in Japan.

I chose the method which interrupted a pipe between compressor and the

condenser with the Solenoid valve at the time of the refrigerator unit

stop to prevent "nekomi".

A refrigerant liquid was stored in the condenser, and this was the purpose

of shortening the start time of the system.

It seems that though 100% of the expected results couldn't get it, a result

by the completed refrigerator unit was a little effective.

And, sufficient attention is necessary because compressor is made to burst

when it is the worst when a pipe is interrupted by accident during the

refrigerator unit operation.

|

PC case

|

|

Case remodeling

The PC case which a refrigerator unit is carried on is the case of the

full -tower.

The first plan intended to arrange a refrigerator unit in the same way

as Vapochill on the upper step inside the case.

But, a refrigerator unit was decided to be put under the case most to prevent

the convection of the hot air, the occurrence of the AC line noise, and

so on, the occurrence of the vibration.

It means that refrigerator unit interferes in M/B.

I moved a panel in the rear and a M/B mounting plate by using JIG-SAW,

DRILL and Riveter.

And, a refrigerator unit was hung with four rubber belts to cope with the

vibration.

A refrigerating unit and the division of the PC were partitioned by using

aluminum board for the heat countermeasure and an AC line noise interception

and prevention of noise.

Therefore, air is discharged from the rear after it was inhaled from the

front and only a refrigerator unit was refrigerated.

|

EVA fixation and the condensation countermeasure (vacuum Insulation CPU

case) of the water

|

|

Vacuum Insulation CPU case

A base board because of the EVA fixation was made to fit each other to

the pattern of M/B, and it shaved an acrylic board with milling-machine.

There are some parts such as a condenser chip and a resistance chip to

avoid though the neighborhood of Socket478 is almost level ground.

And, as for the result of the simulation of the heat conduction which I went for, at least 1.5-inch thickness was necessary for the insulation around EVA.

Therefore, I tried the production of the vacuum Insulation CPU case.

It was the place where I wasn't expecting it, and there was an accident

that a vacuum tore, and time was wasted more than the schedule.

But, I got structure and the structure of the part, know-how such as the

combination of the material by trying a fresh thing.

A user isn't supposed to need to care about the condensation of the water

by the CPU case of the perfect structure.

I think. ....... It isn't easy to keep it in the vacuum for a long time.

|

Code heater

I used the code-shaped heater of "80ohm/m" purchased from "Sakaguchi

E.H VOC Corp." to avoid the condensation of the water to M/B.

It was installed on both sides of M/B with the plastic code of 0.1-inch

outside diameter.

It is very thin, and an inside heater line is not almost the thickness

of the hair.

Because it was difficult to connect it, I was connected by crushing a copper

sleeve.

|

Insulation of the pipe

A pipe on the return side has the possibility that it becomes less than

-40 centigrade.

In that case, a difference in temperature with surrounding temperature

must understand that it is beyond 60 centigrade.

As for being the same as Vapochill, a water drop sticks to the surface

of Insulation with diameter 0.8-inch insulation.

Therefore, diameter 0.8-inch foaming polyethylene and diameter 1.8-inch

AEROFLEX were used.

Even if it is done there, a surface sometimes becomes wet.

|

| Others |

|

Monitor gauge kit

The pressure gauge installed with the owner's hope.

Two pressure gauges are unity types, and it indicates the pressure of the

condensation and the pressure of the evaporation at the same time.

A user can appreciate the condition of the refrigerator unit easily by

that pressure which shows it.

We are made to know that a switch on the front panel and a monitor gauge

kit are refrigerators.

However, it is a PC.

|

FAN control

I chose powerful AC-FAN.

Then, it was decided to use big FAN by the low rotation to get stillness

and cooling performance.

AC-FAN was made variability by using the electric power adjustment utensil

which SCR of the trade name of VARITAP was used for.

Dramatic variability is difficult though VARITAP is simple because a voltage

is only being adjusted.

And, it was the same result though miniature single phase inverter was

used.

|

Temperature controller

It was decided that I used E5CN manufactured by omron.

It has a function beyond Chill-con which Vapo has, and it is used for the

equipment control of the factory.

That use sensor was a T-type. (It can be measured to -200 centigrade.)

Then, it was installed at the surface of EVA.

|

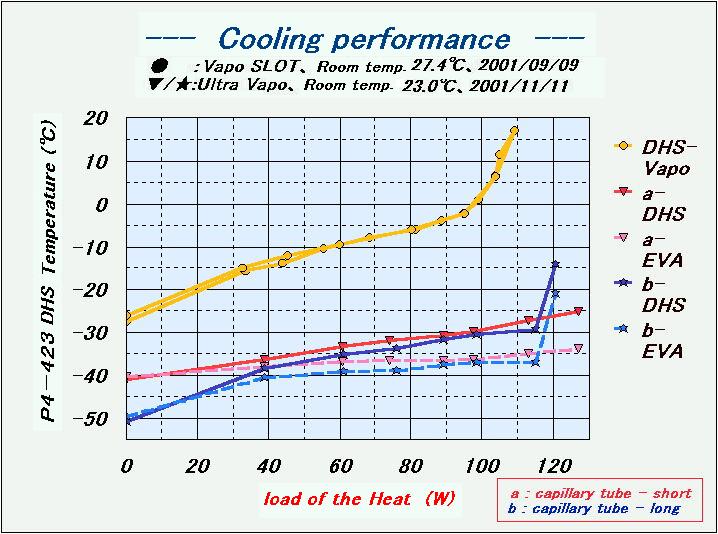

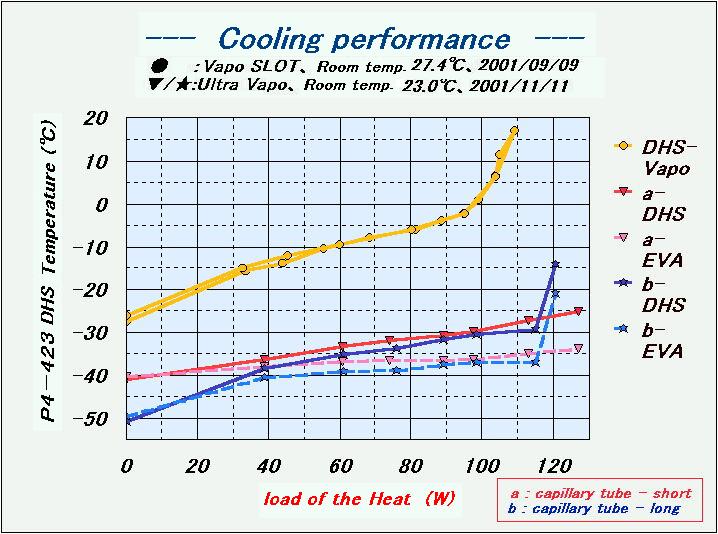

Cooling performance

|

|

A dummy Heat Spreader (It is shown with "DHS" in the following.)

builds in a source of heat and a temperature sensor.

Then, it is shape which is same as Heat Spreader of P4.

The temperature sensor built in is set on position of the core-chip of

the CPU.

Performance evaluation went by using "DHS".

The first explanation is the ability of Vapo SLOT.

This was measured before I took it apart.

"Vapo SLOT" uses R134a. Then, the output of the compressor

being used is only 35W.

Though it is small, this refrigerating unit has wonderful performance,

and it should be admired.

And, the structure of EVA is wonderful, too.

If P4 is aimed , Slot will get cold better than EVA for Socket.

Then, as for the ability of "Ultra Vapo" ....

Operation confirmation was included and tested.

It got the performance expected as a Phase Change Cooling machine which

used R22.

If a load-less is a target, it is possible that it is cooled in -60 centigrade.

However, the hope of the sponsor is Max130W.

If it had Max130W required, a designer necessarily increases a margin.

A red line shows the temperature of "DHS" when a short capillary

tube is used.

And, a pink dotted line shows temperature of EVA which a short capillary

tube was used for.

If a short capillary tube is used, it will endure a load to about 160W.

On the other hand, a blue line is the result when a long capillary tube

is used.

It is suitable for the high summer time of the condensation pressure.

The place which O/C made do P4 a little is enough even for this.

heat resistance of EVA was computed in the next method.

The temperature when refrigerant evaporates is estimated from the pressure

on the low pressure side.

dT is looked for from a temperature to evaporate, and temperature of DHS.

dT is divided by the amount of load.

The result of the calculation was a 0.062〜0.084 centigrade /W by the load

of 60W and more.

It was the best in 10 and more EVA which I made by now.

I want to know it if there is a thing of the performance beyond this EVA.

DHS and the method of the temperature measurement are shown in the next

link.

"Even if EVA gets cold, Core is hot." and "the performance evaluation of Vapochill Socket eva"

|

|

|